Roland MDX-540 Desktop Milling Machine

- Imports STL Files – just like a 3D printer!

- No propriety materials!

- No CNC programming knowledge required!

- Low cost of ownership and no necessary service contracts!

Plus…

- 4-axis, benchtop CNC machine for fast, accurate prototyping

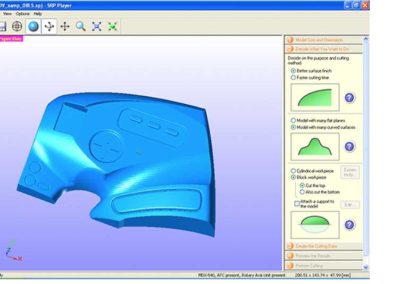

- Bundled with user-friendly CAM software

- Handheld controller and virtual control panel for quick and easy set up

- Max. work area 19.6″ (X) by 15.7″ (Y) by 6.1″ (Z) without rotary axis

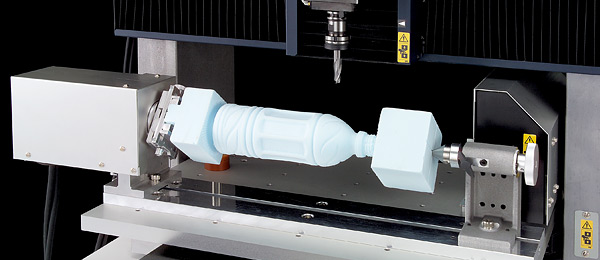

- Optional rotary axis available for enhanced precision and accuracy

“Precision milling really helps students understand what works and what doesn’t in their designs,” says Aerospace engineer Rob Hazlehurst. “It’s a very effective teaching tool.”

Roland MDX-540 CNC machines combine the advanced capabilities of a Subtractive Rapid Prototyping®(SRP) system with the ease-of-use of a benchtop CNC mill to provide a powerful 3D milling device.

Whether for product designers, engineers and other professionals, or for students and educators, the MDX-540 combines advanced capabilities with ease-of-use for the precision milling of a wide variety of plastics, woods, metals and more.

Although the MDX-540 is a highly advanced 4-axis desktop CNC device, it offers a simplified operating system plus included SRP Player CAM software to make prototype production an easy and stress-free experience.

The rotary axis (optional), automatic tool changer (optional), and milling speeds can all be controlled via a simple Virtual Control Panel or the user-friendly software.

SUMMARY

- Subtractive rapid prototyping technology:

- Creates accurate prototypes for complex snap-fit

- Proves part manufacturability better than additive methods

- Handles a wide variety of materials including plastic, resin, wood and non-ferrous metals, and generates a smooth surface finish

- Bundled with 4-axis SRP Player CAM software makes it quick and easy to go from a CAD model to physical part or prototype

- Large 19.6″ (X) by 15.7″ (Y) by 6.1″ (Z) without rotary axis

-

Check out these CO2 car bodies! Click to read the story! Castle View High School | Castle Rock, Colorado.

Optional rotary axis

- Virtual control panel offers additional functions

- Moves tool in vertical, horizontal and transverse directions, and to a user-specified position

- Adjusts the speed of cursor movements for easier origin setting

- Real-time cutting and spindle speed override capability

- Bundled Roland ClickMill™ software

- Surfaces materials, adds holes and rounds edges – all without 3D CAD file

- Spindle speeds of 400 to 12,000 rpm; 400 to 3,000 rpm for positioning and centering

- Supports G-code NC programming language, making it well suited for both professional and educational applications.

- Emergency stop switch and machine cover for clean, quiet and safe work environment

- ZCL-540 rotary axis unit automatically positions parts for unattended 360-degree modeling

Choose the MDX-540 Model That’s Right For You

All MDX-540 models deliver superior performance with a combination of Digital AC Servo motors and Feed Forward Processing commonly used in larger, more expensive machines. In addition to the base-model MDX-540, you can choose from the following options:

MDX-540S

Produce even smoother curves and finer details with the addition of higher accuracy ballscrews for enhanced precision and repeatable production capabilities.

Optional Tool Changer

MDX-540A

Includes an Automatic Tool Changer for uninterrupted milling.

MDX-540SA

Produce smoother curves and finer details with the addition of higher accuracy ballscrews for enhanced precision and repeatable production capabilities, plus an Automatic Tool Changer for non-stop production.

TEC is your Roland DGA Academic Representative for New England!

VIDEO: Producing a Prototype with a Roland MDX-540 Milling Machine