What’s included

- BASF Forward AM Ultrafuse® 17-4 PH (1 kg)

- Packaging for green parts and a voucher toward post-processing*

- Ultimaker Print Core CC 0.4

- Magigoo Pro Metal (50 ml) adhesive

- Free Ultimaker Cura software with optimized metal part slicing features

- Access to exclusive metal FFF e-learning content on Ultimaker Academy

*This voucher is provided by an authorized reseller, following debinding and sintering fees.

Metal parts. Up to 90% cheaper

The Ultimaker S5’s low total cost of ownership and small size makes it easy to adopt and scale an affordable metal 3D printing solution. Compared to CNC and other additive methods, you can save up to 90% creating the metal tools and parts you need.

Freedom to design high-quality steel parts

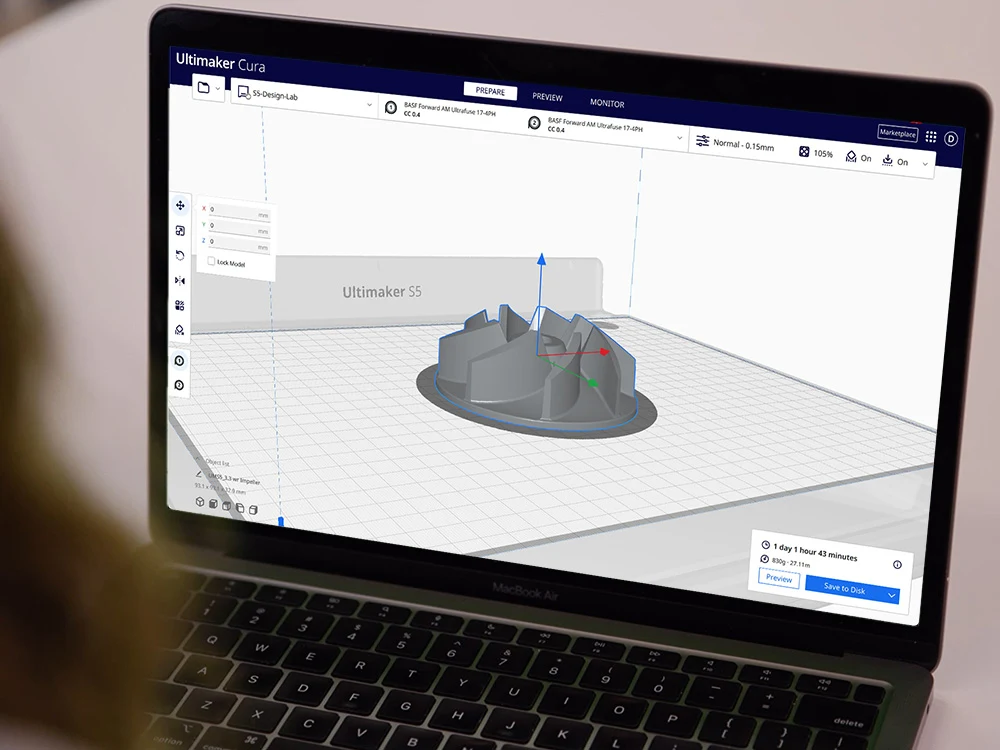

The Ultimaker Metal Expansion Kit allows you to 3D print 17-4 PH stainless steel, offering the freedom to create strong parts with complex geometries at a lower cost than traditional methods. Plus, Ultimaker Cura 5 includes metal FFF features to give you full control and ensure a high-quality metal part.

Now you can decide, plastic or metal?

The Ultimaker Metal Expansion Kit adds the capability of 3D printing either plastic or metal to your Ultimaker S5. Just switch out the print cores to switch between materials. This gives you the flexibility to 3D print using an even wider range of materials all on one machine – from simple PLA or Tough PLA, to engineering-grade polymers, to stainless steel!

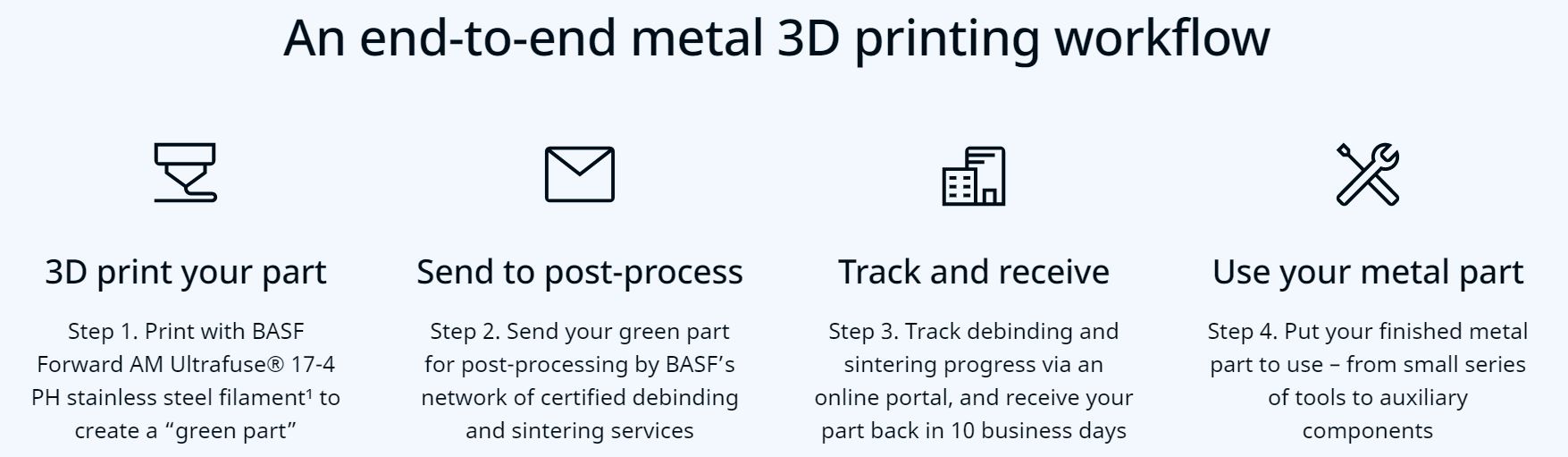

How the magic happens…

- Material: Ultimaker teamed up with BASF to develop BASF Forward AM Ultrafuse® 17-4 PH. This ideal stainless steel material is for high-strength and stiff parts. It is also capable of withstanding the harshest operating conditions thanks to its excellent corrosion and heat resistance. These properties are achieved through a proven catalytic debinding and sintering process used for traditional metal injection molding.

- Software: The Ultimaker Metal Expansion Kit unlocks extra features inside the Ultimaker Cura 5 engine. These make metal print preparation simpler – automatically and accurately compensating for shrinkage that happens during sintering across all axes. You gain better control over your part and increased metal print success.

- Free e-Learning: Not a metal FFF expert? The Ultimaker Metal Expansion Kit gives every user access to an exclusive, 1-hour e-learning course. Get step-by-step guidance through the full workflow. And learn to successfully create high-quality metal parts with an Ultimaker printer.

Post-Processing Your Part

Metal 3D printing with Ultimaker requires no hardware modifications. Simply swap the print cores on your Ultimaker S5, load the material (which is automatically recognized thanks to an NFC chip in the spool), and start your print. The result is a “green” part ready for debinding and sintering.

Each Ultimaker Metal Expansion Kit includes a $50 voucher toward post-processing your 3D print into a full metal part within 10 business days. This is possible via BASF’s network of certified debinding and sintering services. Via an online portal, you can book your part’s post-processing on the calendar and check in on your part’s progress at any time.

Frequently Asked Questions

Which 3D printers are compatible with the Ultimaker Metal Expansion Kit?

The Ultimaker Metal Expansion Kit is designed and optimized for the Ultimaker S5 (plus Air Manager). That’s because we strongly recommend the use of an Air Manager when printing BASF Forward AM Ultrafuse® 17-4 PH material.

Having said that, you can also use the Metal Expansion Kit with the Ultimaker S3. Customers choosing this option should ensure good ventilation and be aware of how the room’s size, number of printers, throughput, etc. can affect air quality.

Will my Ultimaker Metal Expansion Kit include the Ultrafuse® Support Layer and Ultimaker Print Core DD?

The Ultimaker Metal Expansion Kit which includes the BASF Forward AM Ultrafuse® Support Layer and Ultimaker Print Core DD 0.4 is currently only available in Europe.

In other territories (including North America, Brazil, and China), the Metal Expansion Kit is sold without this material and print core at a lower MSRP.

How is the metal 3D printing workflow different to printing plastic filament?

The biggest workflow difference is after 3D printing, during post-processing.

To produce a solid steel part, your print needs to go through a process of debinding (removing the plasticizer in the material) and sintering (heating without melting to stabilize the structure).

Debinding and sintering is most cost-effective when outsourced. That’s why the Ultimaker Metal Expansion Kit includes everything to make this workflow hassle-free. For example, Ultimaker Cura automatically accounts for shrinkage when preparing your part. And you get access to the BASF Forward AM Debinding and Sintering Order Management Portal, as well as packaging for your part and a voucher toward its post-processing.

Can I buy the equipment to debind and sinter the parts myself?

While you will likely find it more cost-effective to outsource the post-processing of your metal 3D prints, it is possible to debind and sinter in house with the right equipment.

Ultimaker has partnered with Xerion, an additive manufacturing systems specialist for complex metal parts. Their Fusion Factory compact integrates affordable debinding and sintering in one machine with a footprint of only 1.2 m x 1.2 m. Click here to learn more.

What can I 3D print with the Ultimaker Metal Expansion Kit?

Our customers have seen great results and impressive cost-savings by 3D printing stainless-steel auxiliary components, functional prototypes, and small tools.

For real-life examples of these, click here.