3D Systems ProJet MJP Series 3D Printers

Precision plastic, elastomeric, wax and composite parts with MJP 3D printers

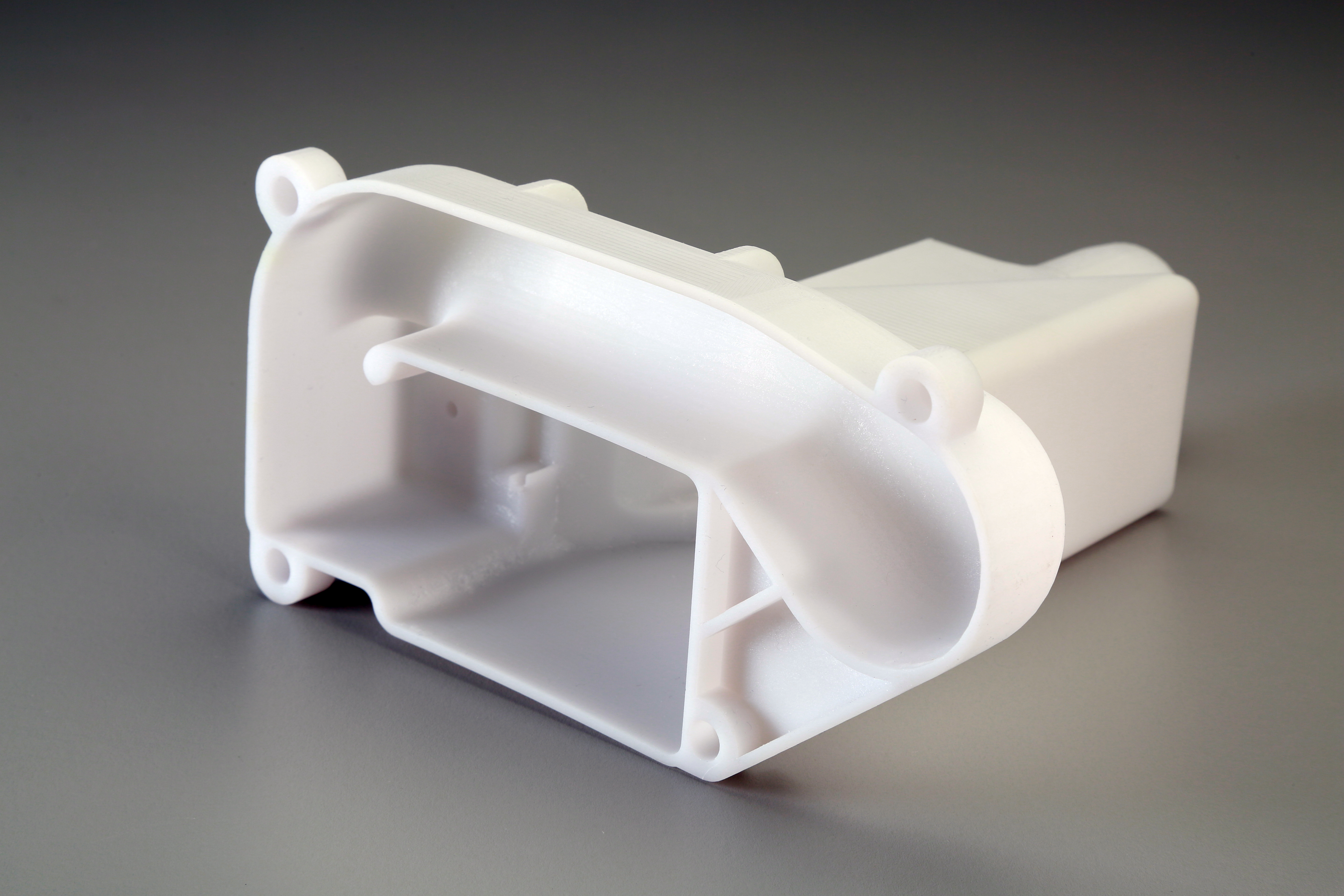

MultiJet Printing (MJP) technology produces high fidelity, true-to-CAD parts, with fast print times, easy operation and simple post-processing for high productivity and true simplicity, from file to finished part. The wide range of VisiJet® materials for the ProJet MJP Series enables a broad set of applications for concept modeling, form and fit testing, functional prototyping, fluid flow analysis, rapid tooling, jigs and fixtures, casting patterns and medical applications requiring USP Class VI and/or ISO 10993 certification.

More Parts, Faster

The combination of fast print speeds, easy operation, and simple post-processing with 3D Systems’ MJP makes getting accurate, high-quality parts faster than ever without spending extra time on manual processes.

True-to-CAD Fidelity

Get sharper part corners and edges with 3D Systems MJP and have even the smallest features survive post-processing, allowing for greater geometric freedom.

Streamlined File-to-Part Workflow

Take advantage of 3D Sprint®, 3D Systems’ exclusive additive manufacturing software for plastic printers to streamline your workflow across file preparation and optimization to print management.

Easy Post-Processing

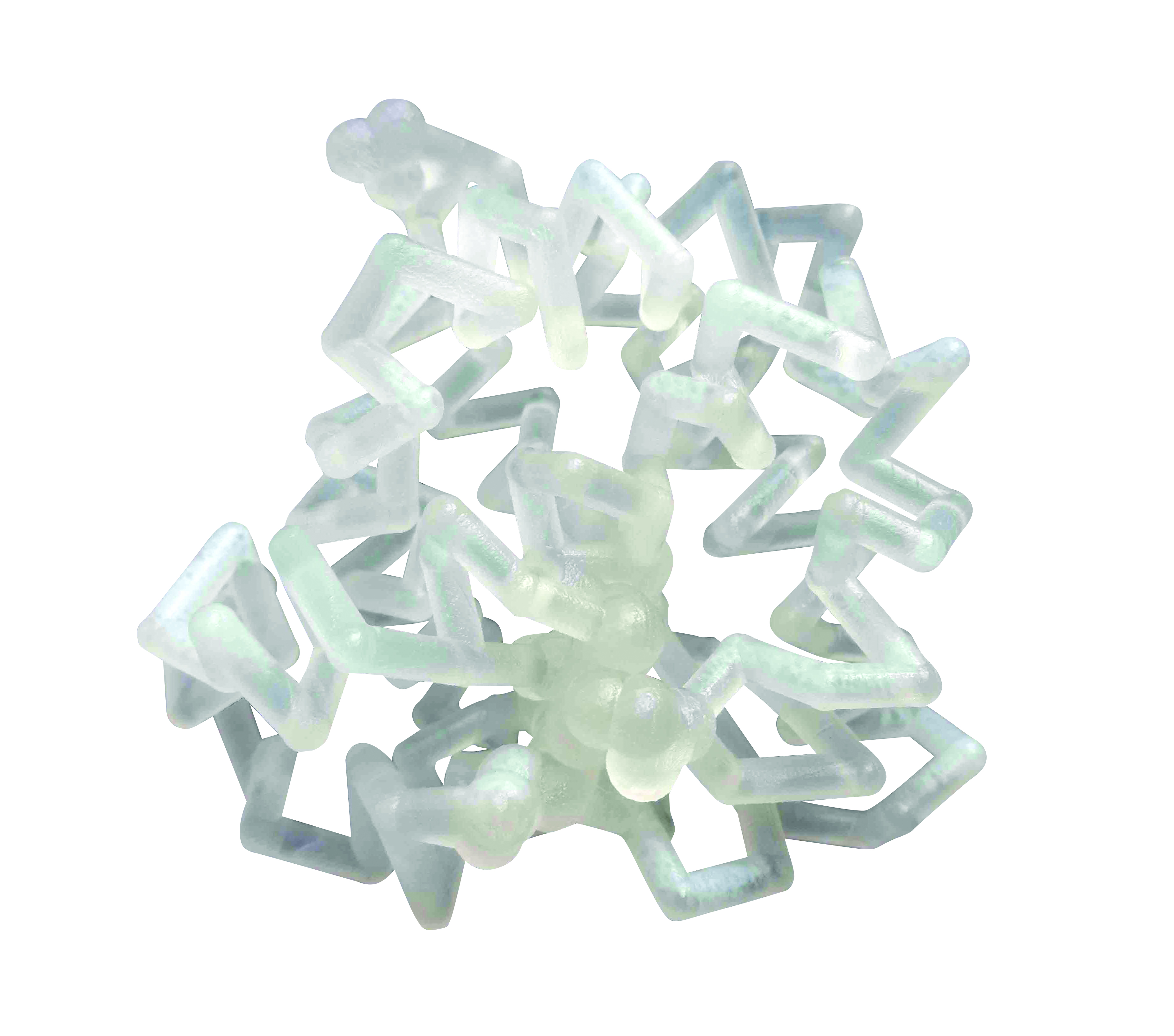

Hands-free post-processing enables complete removal of supports from all areas without damaging the part or sinking hours into the process.

MJP Applications

MJP delivers true-to-CAD part accuracy in a diverse range of plastic, elastomeric, composite, and wax materials for fast and affordable 3D printed parts across industries. MJP is an excellent choice for:

- Concept modeling

- Communication, sales and marketing model

- Rapid design iteration for rigid plastic or elastomeric products

- Validation prototyping

- Design verification and testing

- Assemblies validation, including snap-fits and multi-material assemblies

- Water-tight applications, fluid flow visualization

- Functional testing of plastic and elastomeric products

- Over-molding

- Biocompatible medical devices requiring USP Class VI and/or ISO 10993 capability

- Jigs, fixtures, and tools

- Patterns, dies, and molds for rapid tooling

- Investment casting patterns production for industrial applications

- Investment casting patterns production for jewelry applications

Send me a quote!

ProJet MJP 2500/2500 Plus

MultiJet Printing Quality, Speed and Ease of Use Made Accessible

Highlights:

Up to 3x higher 3D printing speeds than similar class printers and finished part delivery up to 4x faster with 3D Systems MJP EasyClean System

Capable of printing in rigid, engineering-grade, high temperature resistant, elastomeric or biocompatible materials, in clear or in a range of opaque colors

Perfect for concept modeling, rapid design iteration and validation, jigs and fixtures, patterns and molds

Software:

3D Sprint

ProJet MJP 2500 IC

Tool-less production of 100% wax casting patterns

Highlights:

High quality small to mid-sized wax patterns that fit directly into a standard foundry casting process

Ideal for customized metal components, bridge manufacturing and low volume production

VisiJet® M2 ICast 100% wax material delivers the same melt and burn-out characteristics of standard casting waxes

Software:

3D Sprint

ProJet MJP 2500W

Fast and affordable jewelry wax pattern printer

Highlights:

Pre-series and series production of jewelry metal pieces

Customized jewelry metal pieces manufacturing

Figurines, replicas, collectibles and art pieces

Software:

3D Sprint

3D Connect

ProJet MJP 5600

Large format, multi-material composite parts in a single build

Highlights:

Produce over-molded parts, multi-material assemblies, rubber-like components, jigs and fixtures, dies and more.

Five base materials: rigid white, black or clear, elastomeric black or natural, plus more than 100 composite combinations

Print parts up to half a meter long—or several smaller parts—in a single build

Software:

3D Sprint

ProJet MJP 3600 Series

High capacity, resolution and performance for MultiJet 3D printing.

Highlights:

Print in a choice of seven durable plastic materials

Choose between the ProJet MJP 3600 or 3600 Max 3D printers, depending on build volume and resolution requirements

Print assemblies, including snap-fit, parts for fluid flow visualization, and USP Class-VI compatible medical applications

Software:

3D Sprint